At Silkbridge, we pride ourselves on our vision of combining British innovation with Chinese manufacturing efficiency. Founded in 2014 by a British design engineer, our company is based in Guangdong Province, China, and has become a leader in delivering high-quality manufacturing solutions.

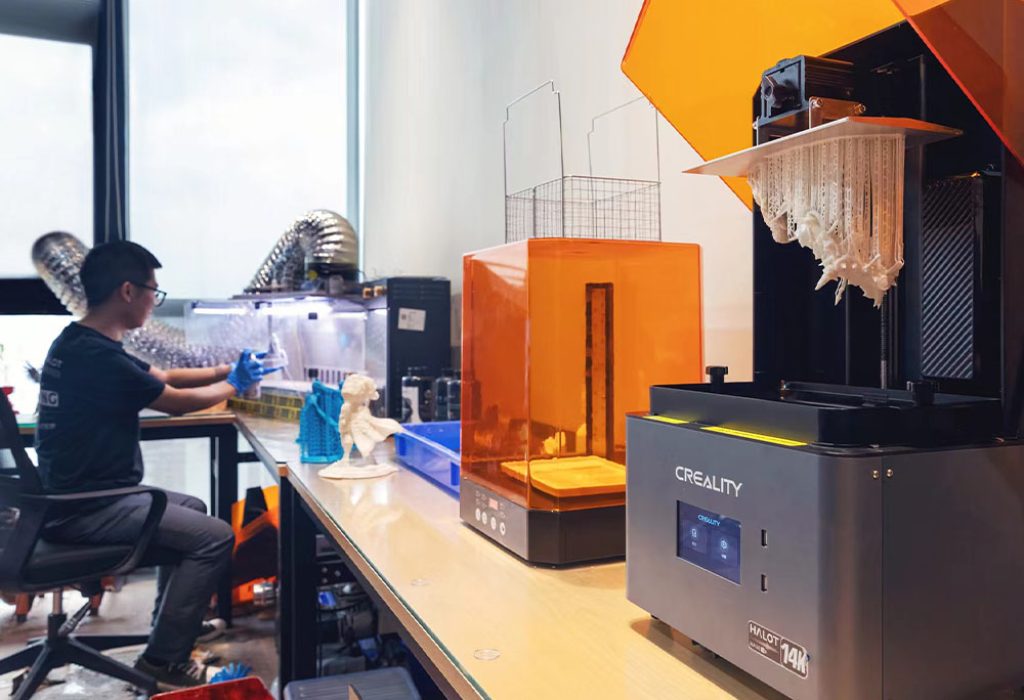

Our Research and Development team, with decades of experience, is dedicated to developing cutting-edge electronic and innovative ODM products. Having won multiple European design awards, our R&D department drives the creation of products that meet the highest standards of innovation and functionality. From initial concept to final design, we ensure every step of development is meticulously planned. We offer a full-service product design and development solution, blending Western design with Chinese manufacturing to bring your ideas to life. Our multidisciplinary team of over 20 designers and engineers from Western Europe and China ensures your product is designed for optimal performance and efficiency from the ground up.

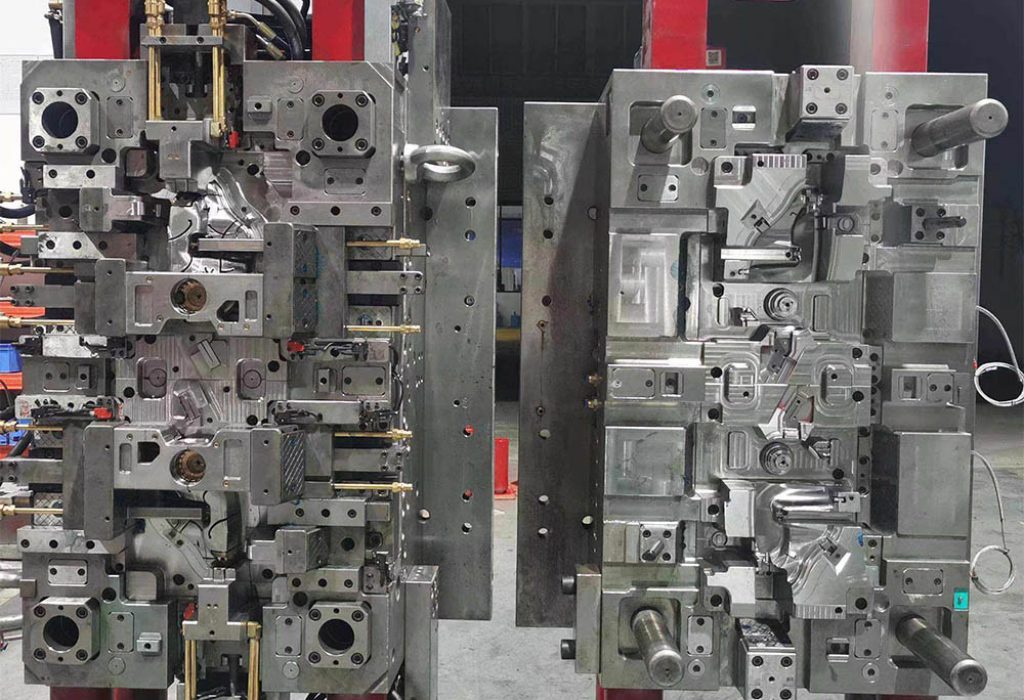

At Silkbridge, precision and quality are at the heart of our plastic injection mold-making services. Our cutting-edge facility is equipped with over 30 CNC machines, 25 EDM (Electrical Discharge Machining) units, wire-cutting machines, and a wide array of grinding and milling machines. With this comprehensive suite of advanced equipment, we are able to craft molds with exceptional accuracy and precision, ensuring the highest level of performance for your plastic injection molding projects.

We produce over 30 million plastic injection parts annually, utilizing 100 state-of-the-art injection molding machines ranging from 180 tons to 1200 tons. Our advanced machinery, combined with rigorous quality control, ensures that we can meet the diverse needs of industries from consumer electronics to automotive and medical devices. With ISO 9001 and additional certifications in plastic production and electronic product manufacturing, quality is embedded in everything we do.

Silkbridge operates fully automated PCB SMT (Surface Mount Technology) lines equipped with top-tier machinery from leading global brands, ensuring precision and consistency throughout the production process. These lines have the capacity to handle both high-volume and small-batch production with minimal setup time, making them highly adaptable to different project requirements. With the integration of AOI (Automated Optical Inspection) and X-ray inspection, we ensure that every PCB we produce meets exacting standards for performance and durability. Designed and developed in-house by our award-winning R&D department, our PCBs are a critical component in delivering high-quality electronic products to our global clientele.

Our assembly lines produce hundreds of thousands of fully assembled products each month. These assembly processes are conducted in controlled environments, including anti-static and dust-free, temperature-controlled rooms to ensure the highest standards of electronic product assembly. Our rigorous quality control process spans from IQC (Incoming Quality Control) of raw materials, through to multiple in-process inspections, and ends with a thorough final packaging inspection to guarantee every product meets exacting standards.

We offer a full-service solution that covers product development, plastic, metal, electronics, and final product assembly—all in-house. This integrated approach not only allows us to control the quality at every stage but also simplifies the process for our customers. Rather than dealing with multiple factories, our clients benefit from working with a single point of contact throughout their project.

Additionally, we provide comprehensive distribution services, including DDP shipping, where we manage customs clearance, duties, and import taxes in the destination country. Our customers can sit back and wait for their products to arrive without any logistical hassles. Available as Air, Sea or Train freight according to the customers needs for timing and cost.

Our main markets are the USA, Western Europe, and Japan, and we are proud to have developed and produced iconic products sold worldwide in retail stores such as Walmart and Costco as well as online platforms such Amazon. At Silkbridge, our goal is to offer a one-stop-shop service, making it as simple as possible for our customers to complete even the most complex manufacturing projects.

If you have any other questions, please contact us.

Silkbridge offers a full-service solution for electronic product development and manufacturing. Our services include plastic injection molding, PCB development and assembly, electronic product assembly, and final product packaging. We handle design, development, and manufacturing all in-house, ensuring high-quality and efficient production.

Silkbridge specializes in the electronics, fitness, medical, and consumer goods industries. We have extensive experience designing and producing products for global markets, with clients ranging from tech companies to medical device firms.

Yes, we manage the entire process from concept design to final product assembly and packaging. Our factory includes dedicated areas for mold making, injection molding, PCB assembly, and electronic product assembly, allowing us to oversee quality at every stage.

We are ISO 9001 certified and hold additional certifications specific to plastic production and electronic product manufacturing. This ensures we meet strict international standards for quality and safety in our products and processes.

Quality control is at the heart of what we do. Each department follows strict protocols to maintain high quality, from precision measurement in mold-making to automated inspections in injection molding and rigorous testing during assembly. We keep our defect rate extremely low, as seen in our past projects.

Absolutely. Our team of over twenty designers and engineers combines Western design expertise with Chinese manufacturing capabilities. We can assist with product design, prototyping, and even software development, ensuring that your product is optimized for functionality, aesthetics, and manufacturability.

© 2024 Dongguan Silkbridge Electronic Technology Co., Ltd.