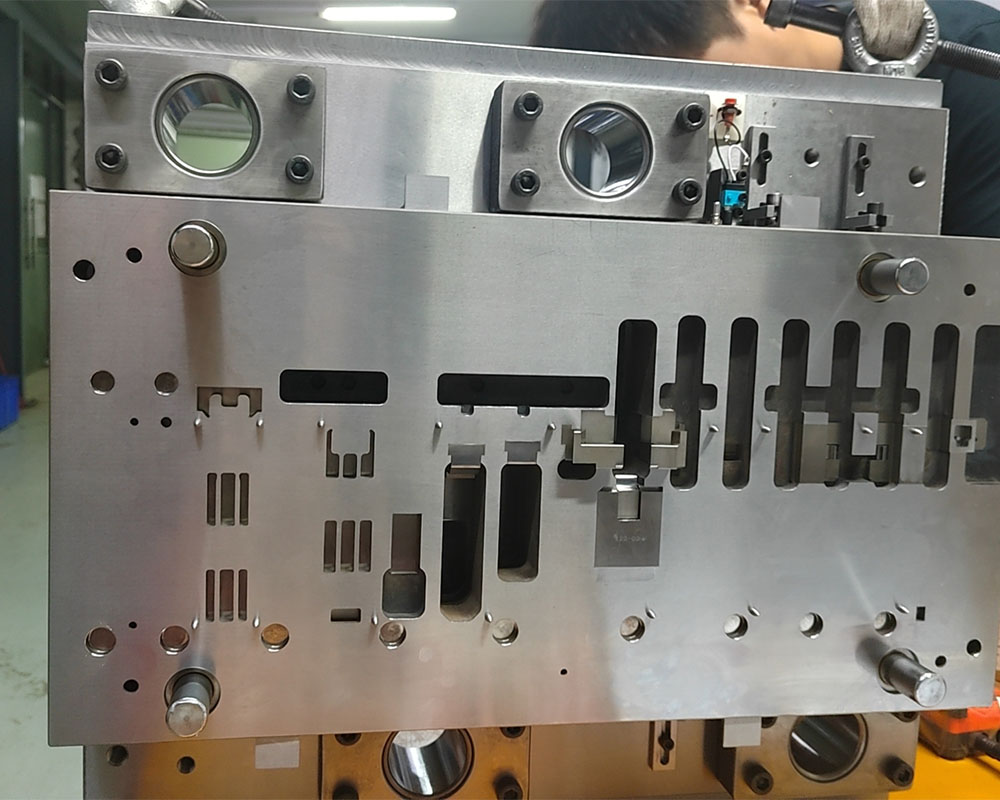

Our mold-making expertise is further enhanced by 25 high-precision EDM (Electrical Discharge Machining) machines, including advanced models from the industry-leading brand Sodick. Known for their superior quality and precision, Sodick EDM machines allow us to produce complex and intricate mold components with extreme accuracy. These machines are particularly effective in creating sharp corners, deep cavities, and other fine details that traditional machining cannot achieve. Our range includes a large, double-operation EDM machine, capable of working on two different operations simultaneously, dramatically increasing efficiency while maintaining the same high level of precision. With Sodick’s cutting-edge linear motor technology, our machines provide consistent, repeatable accuracy, even for the most challenging geometries, ensuring that every mold we produce meets exact specifications. These EDM machines are integral to delivering the high quality, durability, and precision that our customers expect, particularly in industries where tolerances are extremely tight, such as electronics, medical devices, and automotive manufacturing.