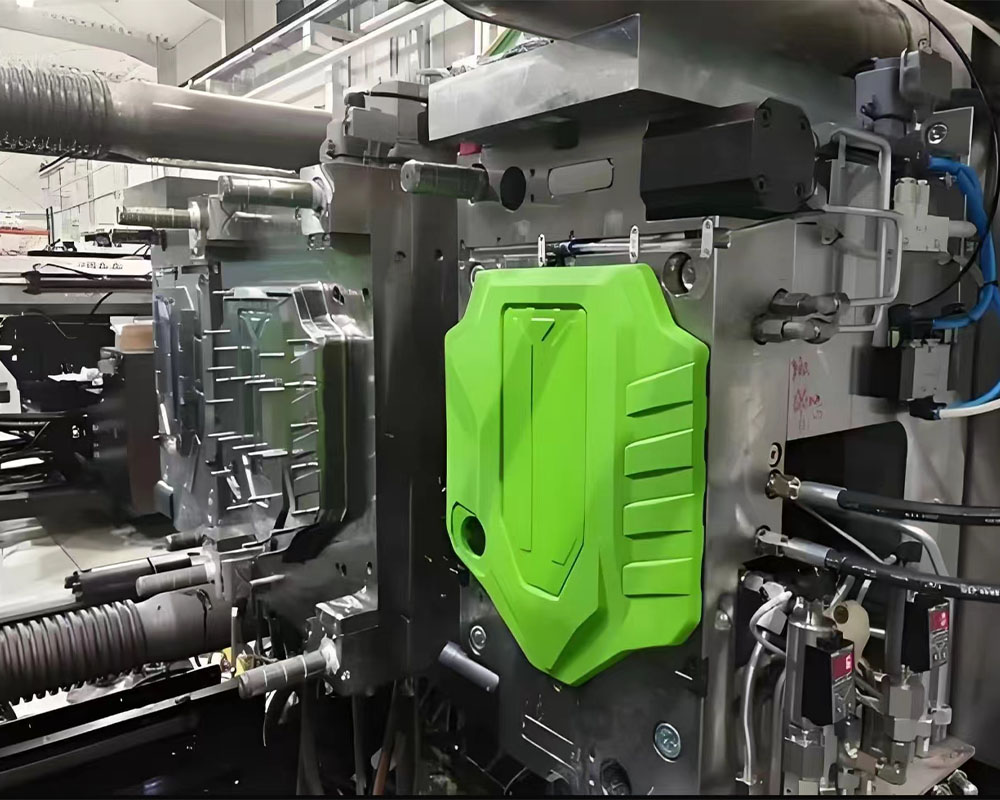

At Silkbridge, quality is built into every stage of the production process. Our quality control starts with the incoming materials, which are inspected to ensure they meet all required specifications. Throughout the injection molding process, we conduct continuous in-process inspections to monitor critical parameters like mold temperature, injection pressure, and cycle times. We utilize advanced inspection equipment, including CMMs (Coordinate Measuring Machines), to ensure that each part meets tight dimensional tolerances. For medical-grade and high-precision parts, additional inspections, including surface finish analysis and material property tests, are performed. Our final inspection process includes visual checks, functional tests, and packaging inspections to ensure that every part that leaves our facility meets the highest standards of quality.