Understanding LED PCB Boards: The Backbone of Modern Lighting

What Is an LED PCB Board?

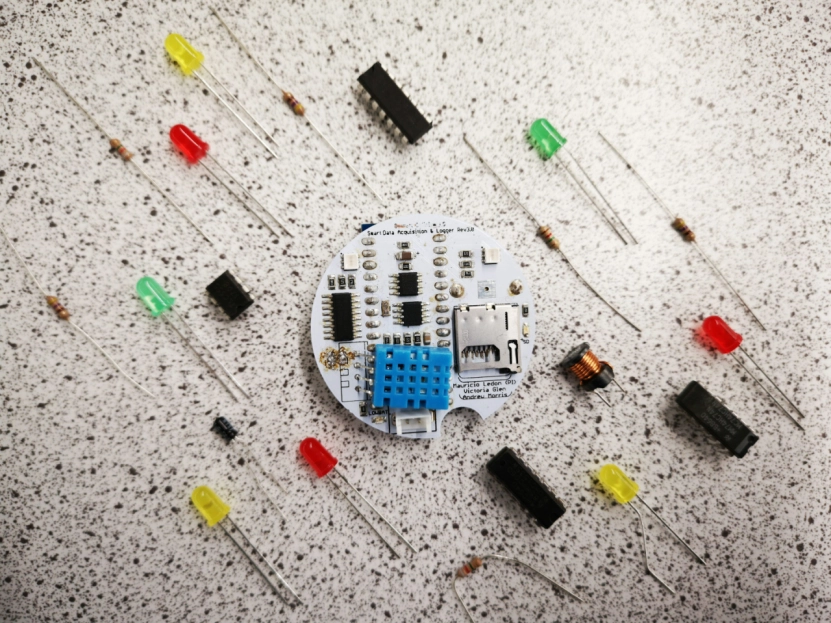

An LED PCB board is a unique circuit panel crafted to sustain and energize light-emitting diodes (LEDs). It delivers vital electrical links while adeptly handling heat dispersal. This ensures enduring functionality. The primary elements of an LED PCB consist of a base layer (like aluminum, FR4, or pliable substances), copper pathways, and an insulating coating that boosts heat transfer.

LED PCBs are pivotal in contemporary illumination uses, spanning from household gadgets to vast industrial setups. The use of potent LEDs calls for effective heat management. Consequently, aluminum PCB boards for LEDs emerge as a favored option. These parts, whether in LED strip PCB boards or expansive LED display PCB boards, determine sturdiness, productivity, and overall lighting quality.

Types of LED PCBs for Different Applications

LED PCBs exist in diverse forms, each suited to particular purposes. The most widespread varieties include:

- Aluminum PCB for LED: Renowned for its outstanding heat dispersal, aluminum PCBs are frequently utilized in robust LED scenarios like vehicle headlights and factory illumination.

- Flexible PCB for LED: These panels employ adaptable bases, rendering them perfect for curved lighting setups, wearable devices, and small electronic layouts.

- Copper-based PCBs: Though less typical, these highly conductive LED PCBs provide superb electrical output for niche uses.

Typical uses encompass LED strip PCB boards in building lighting and LED display PCB boards for electronic signs. Each kind of PCB board for LED lights fulfills a distinct purpose. It guarantees peak performance, efficiency, and durability.

Why Aluminum LED PCBs Dominate High-Performance Lighting

Advantages of Aluminum PCB Boards for LEDs

Aluminum PCB boards for LEDs present numerous benefits that render them essential in top-tier lighting solutions:

- Remarkable Thermal Conductivity: Aluminum PCBs shine in dispersing heat, averting LED breakdowns and boosting productivity. This suits them well for intense applications, such as factory floodlights and car headlights.

- Increased Resilience: They resist elevated temperatures and external pressures. Thus, aluminum PCBs function dependably in tough settings.

- Light and Budget-Friendly: Compared to copper alternatives, aluminum LED PCBs strike an ideal mix of reduced weight and affordability. This makes them a broadly embraced choice.

Design Considerations for Aluminum LED PCBs

When crafting an aluminum PCB board for LED uses, the layout must address several aspects:

- Layer Arrangement: The usual setup features an insulating layer, an aluminum foundation, and a copper circuit to heighten output.

- Heat Control: Suitable thermal routes must be woven into the plan to maximize heat dispersal.

- Tailoring: Power strength, dimensions, and attachment methods should be tweaked to fulfill specific lighting demands.

Custom LED PCB boards enable producers to devise solutions fitted to distinct lighting needs. These range from powerful industrial systems to small smart home uses. Skillful LED PCB board design ensures the panel meets all required performance, safety, and longevity standards.

Flexible LED PCBs: Innovating Compact and Curved Lighting Solutions

Benefits of Flexible LED PCB Designs

Flexible LED PCB designs have transformed lighting applications by permitting greater flexibility and ingenuity. Their chief advantages include:

- Versatility in Shapes: Unlike stiff panels, flexible LED PCBs can curve, twist, and fit uneven surfaces. This makes them excellent for wearables, rounded screens, and vehicle interiors.

- Compact & Light: Their slim and featherweight build suits them for tight electronic uses where space is limited.

- Boosted Toughness: Flexible materials allow these PCBs to endure shakes and physical strain, prolonging their life.

Applications of Flexible LED PCBs

Flexible PCBs for LED uses are broadly applied across industries, such as:

- Vehicle Interiors: Cutting-edge ambient lighting systems leverage flexible LED PCB technology to craft engaging experiences.

- Healthcare Tools: Small, bendable lighting options improve visibility in medical settings.

- Gadgets: Flexible LED PCB boards are vital in foldable displays and smart wearable devices.

A notable instance is LED strip PCB boards in smart home lighting systems. These flexible LED PCB boards foster creative designs. They blend smoothly into modern home automation setups.

From Design to Assembly: How LED PCBs Are Manufactured

How to Make an LED PCB Board

The LED PCB creation process entails several key stages to ensure accuracy and productivity:

- Blueprint Creation: Engineers devise detailed circuit plans based on performance needs.

- Material Choice: Picking the right base, such as aluminum or pliable substances, ensures top functionality.

- Etching & Path Formation: The copper layer is carved to form exact conductive routes.

- Part Placement & Bonding: LEDs and other components are fixed onto the PCB.

- Quality Checks: Each LED PCB undergoes thorough tests to confirm reliability and adherence to standards.

LED PCB assembly demands advanced tools and skill to guarantee top-notch production. Grasping how to make LED PCB boards aids in refining manufacturing efficiency. It also helps achieve excellent product output.

Choosing the Right LED PCB Board Manufacturer

Picking a trustworthy LED PCB board manufacturer is crucial for ensuring product excellence. Key factors include:

- Skill in Aluminum & Flexible LED PCBs: Producers adept in these materials yield superior results.

- Standards & Compliance: Seek suppliers with ISO and sector-specific credentials.

- Customization Options: A maker’s ability to offer custom LED PCB boards tailored to unique needs is vital.

Top China LED PCB board suppliers provide high-quality production skills. They ensure firms receive dependable and cost-effective LED solutions.

Real-World Applications of Advanced LED PCBs

Automotive Lighting Systems

Aluminum LED PCBs are extensively used in vehicle lighting applications. Their high thermal conductivity ensures top performance in headlights, brake lights, and cabin illumination. China LED PCB assembly services deliver quality solutions for the automotive field.

Consumer Electronics and Industrial Displays

Flexible LED PCBs are reshaping consumer gadgets, enabling foldable screens, smart wearables, and industrial LED displays. High-power LED display PCB boards are key in digital signs and large advertising uses.

Silkbridge’s Custom LED PCB Solutions: Precision Meets Innovation

Silkbridge excels in top-tier LED PCB board design, creation, and assembly. With proficiency in aluminum, flexible, and dense LED PCBs, Silkbridge offers advanced solutions for varied lighting uses. Whether you need custom LED PCB boards or large-scale LED PCB assembly, our crew ensures precise engineering and steady performance.

FAQs About LED PCB Boards

What is an LED PCB board, and how does it work?

An LED PCB board is a circuit panel built to support and power LED parts. It ensures electrical links while managing heat dispersal, which is critical for LED durability.

What are the benefits of aluminum PCBs for LED projects?

Aluminum PCBs offer superb thermal conductivity, cutting heat buildup and enhancing LED output and lifespan. They are sturdy and ideal for potent LED uses.

Can flexible LED PCBs withstand high temperatures?

Yes, flexible LED PCBs are made with heat-tolerant materials. This makes them apt for dynamic and warm settings.

How do I choose a reliable LED PCB board supplier?

Check for credentials, manufacturing experience, and customization skills to ensure quality and fit.

What is the process for custom LED PCB assembly?

It includes blueprint design, material picking, etching, part placement, and quality tests for dependability.

Are Silkbridge’s LED PCBs compliant with international standards?

Yes, Silkbridge’s LED PCBs meet global benchmarks, ensuring safety, efficiency, and resilience for diverse uses.

Ready to Elevate Your LED Projects? Partner with Silkbridge

Silkbridge provides expert LED PCB customization services to match your distinct project needs. Whether you seek high-output aluminum PCBs or flexible LED PCB solutions, we deliver pioneering technology and precise engineering. Contact Silkbridge today for a free consultation at contact@silkbridgeltd.com or reach out via WhatsApp: https://wa.me/8618122838771 to explore our creative LED PCB solutions.